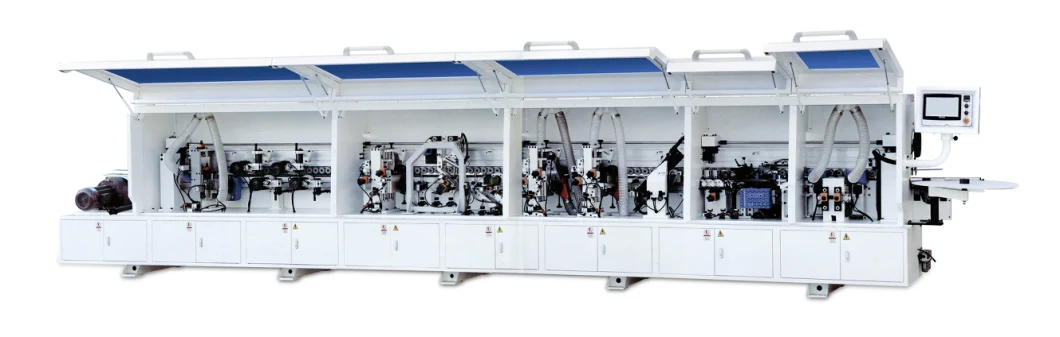

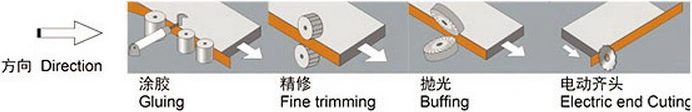

1. Working Process:

Pre-heating, Gluing, Fine trimming, Polishing, Electric and Cutting.

2. Application:

This machine is mainly used for the straight edge banding of MDF, Solid Wood Boards, PVC

Board and Shaving Board. It very applies to the manufacturers who produce panel type

Furniture.

3. Characteristics:

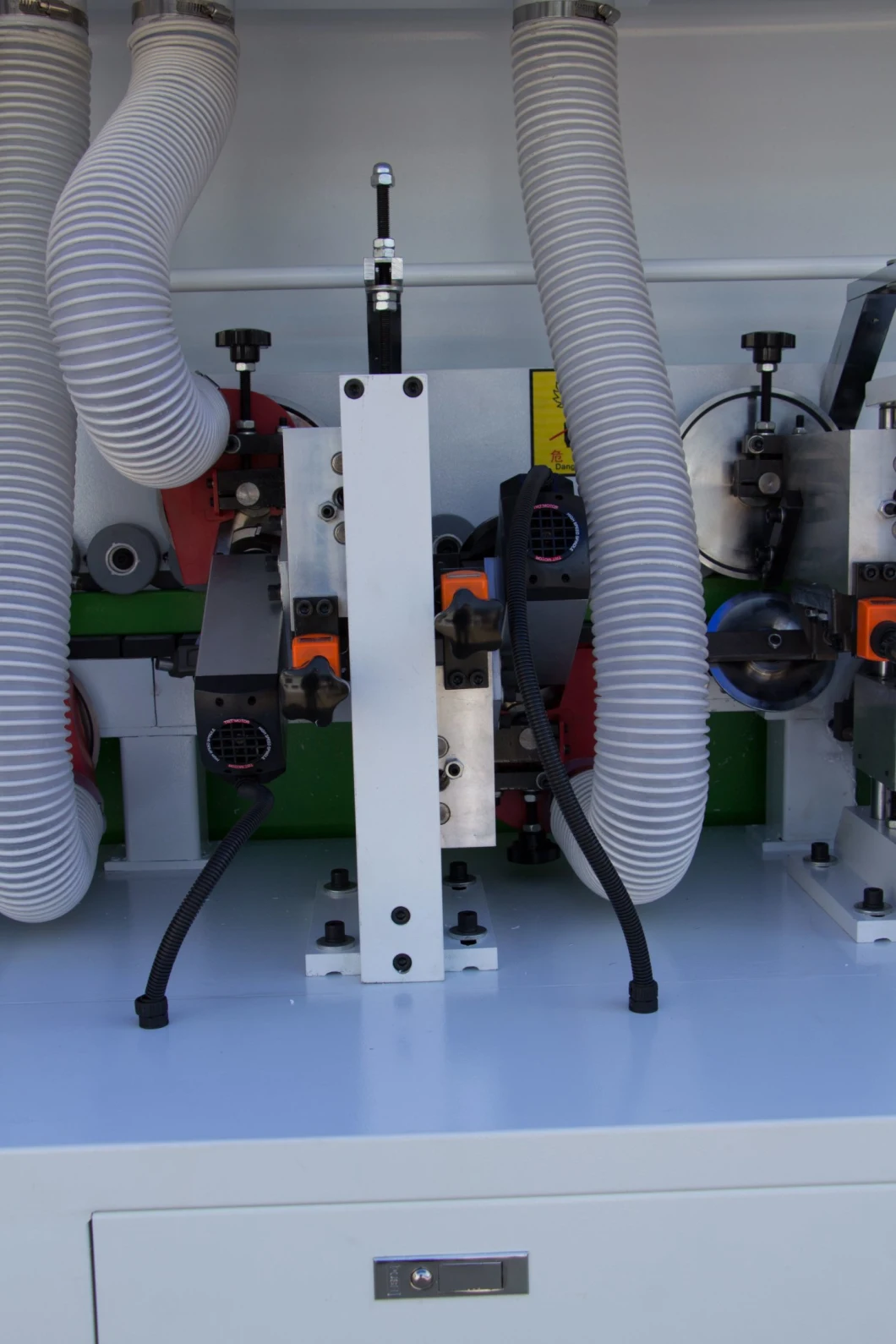

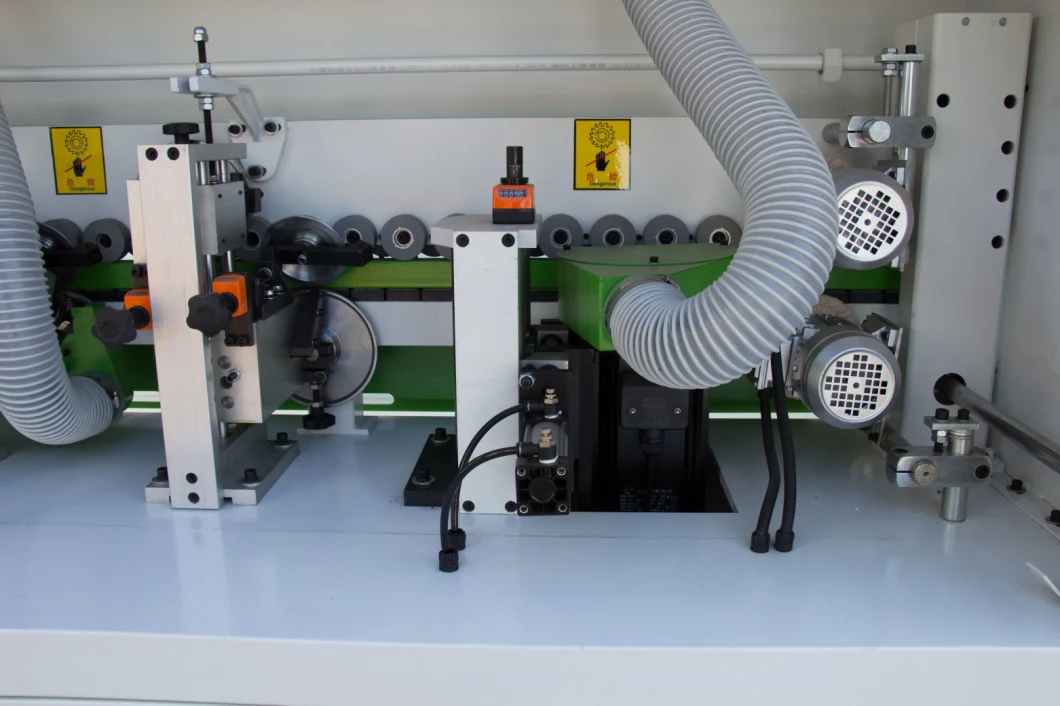

- panels support roller which can be extended on the entire length of the machine.

- exhaust outlets

- electrical cabinet with padlockable main switch and overload motor protection

- infeed and outfeed emergency push button

- it is positioned at machine infeed, easy to be reached from operator's side

- display for the control/set up of the glue working temperature

- manual adjustment of presser with automatic positioning of the operating groups according to the

panel thickness

4. Parameters:

| Panel thickness | 10-60mm |

| Enging thickness | 0.4-3mm |

| Min.Width of panel | ≥80mm |

| Min. Length of panel | ≥160mm |

| Max.size of tape higher than panel(each side ) | 2mm |

| Panel feeding speed | ≤20mm/min(variable speed) |

| Pneumatic power | 0.7Mpa |

| Power | 380V 3N/PE 50Hz Can be customzied |

| Panel feeding motor | 1.5KW |

| Glue axis motor | 0.75kw |

| Edge-cutting motor | 3kw*2 200Hz 12000r/min |

| Rough triming motor | 1.1kw*2 200Hz 12000r/min |

| Fine trimming motor | 0.5kw*2 200Hz 12000r/min |

| Buffing motor | 0.25kw*2 50Hz 2800r/min |

| Heating power of glue tank | 2.5KW |

| Secondary heating power | 0.12KW |

| Lnstalled power | 9.57KW |

| Total current | 19.13A |

| Glue temperature fo readging (reference) | 180-200ºC |

| Overall dimensions | 6585*970*1520mm |

| Weight | 2600kg |

contact with us

Mobile : +86 18615216576