Machine function:

Pre-heatinggluing,end cutting rough trimming ,fine trimming ,scraping ,buffing

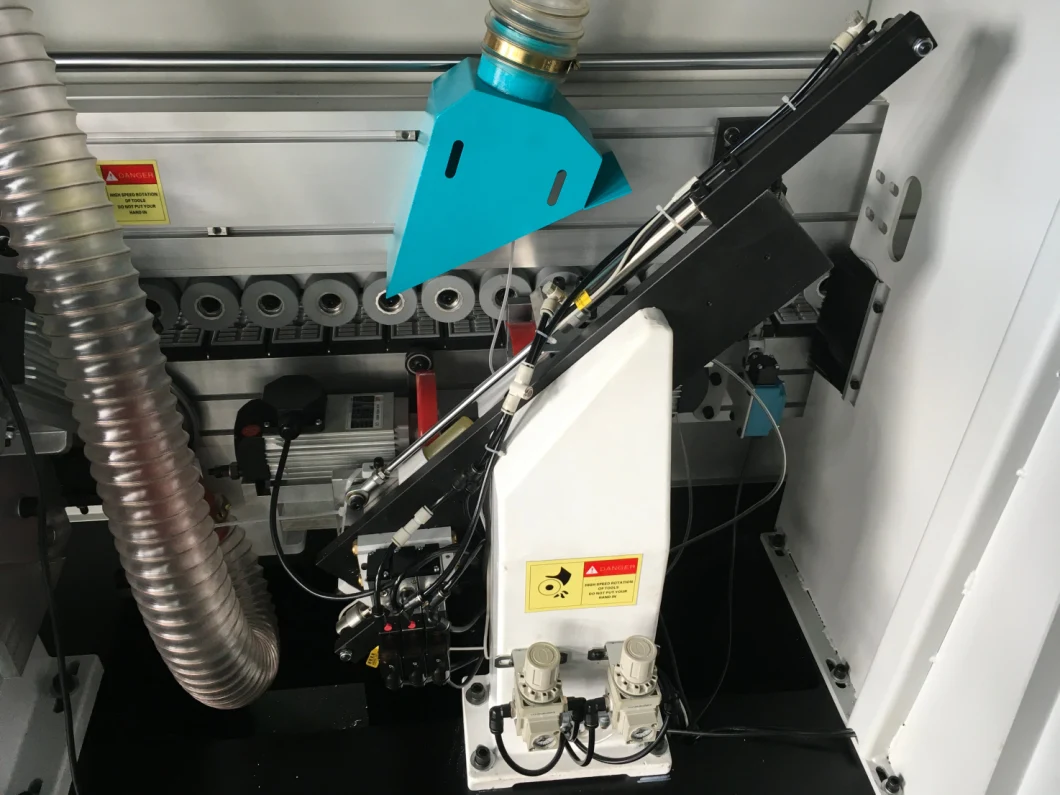

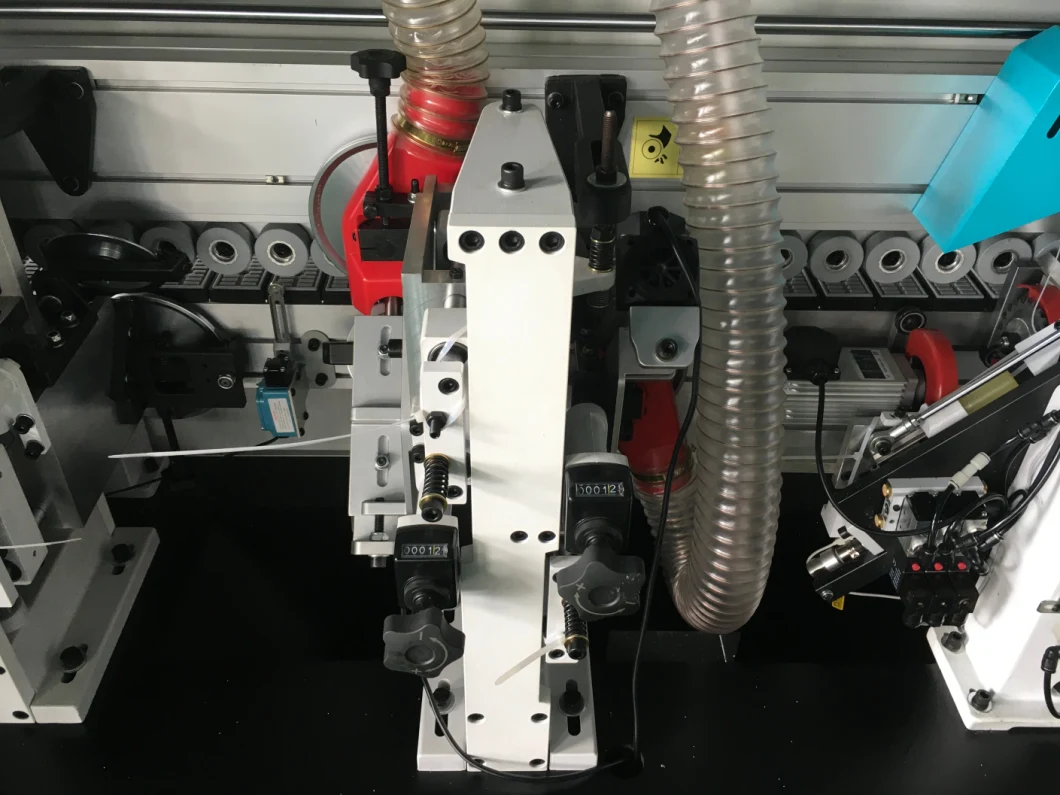

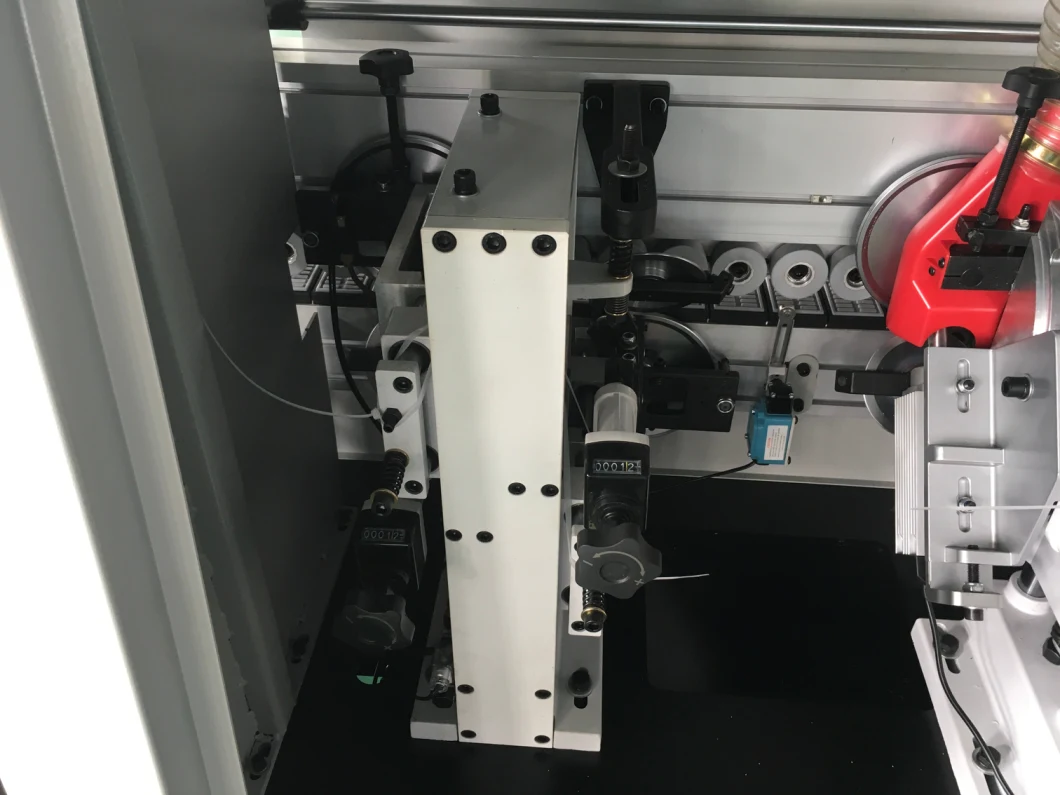

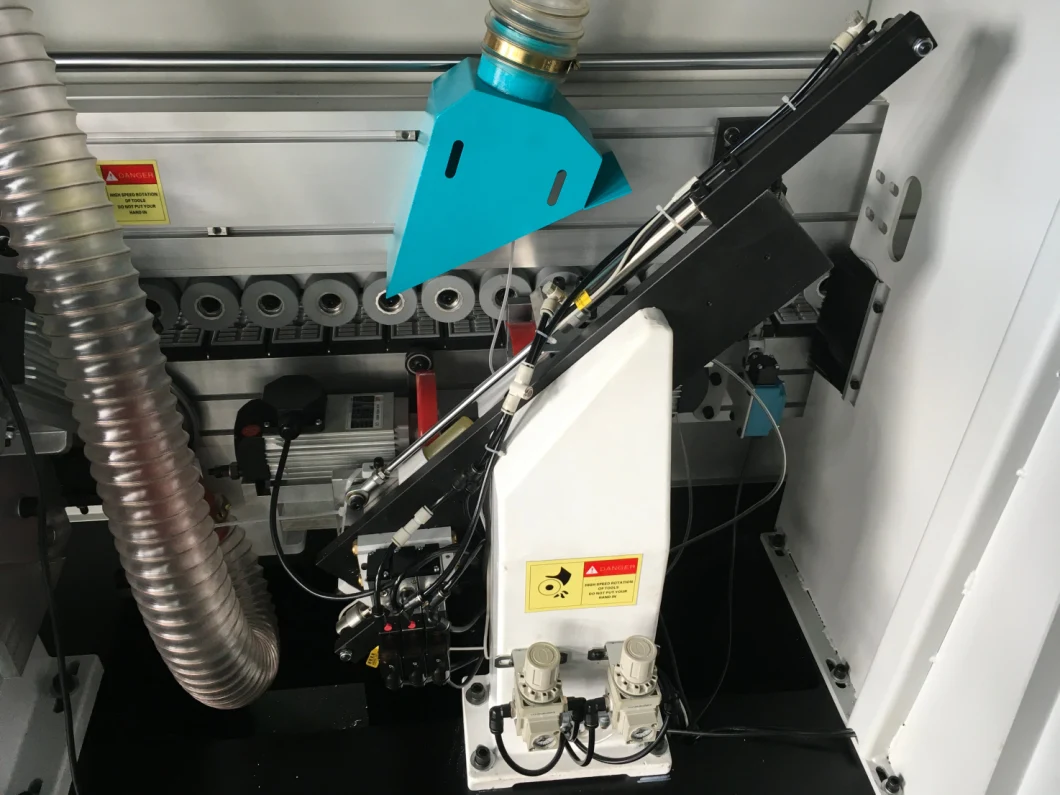

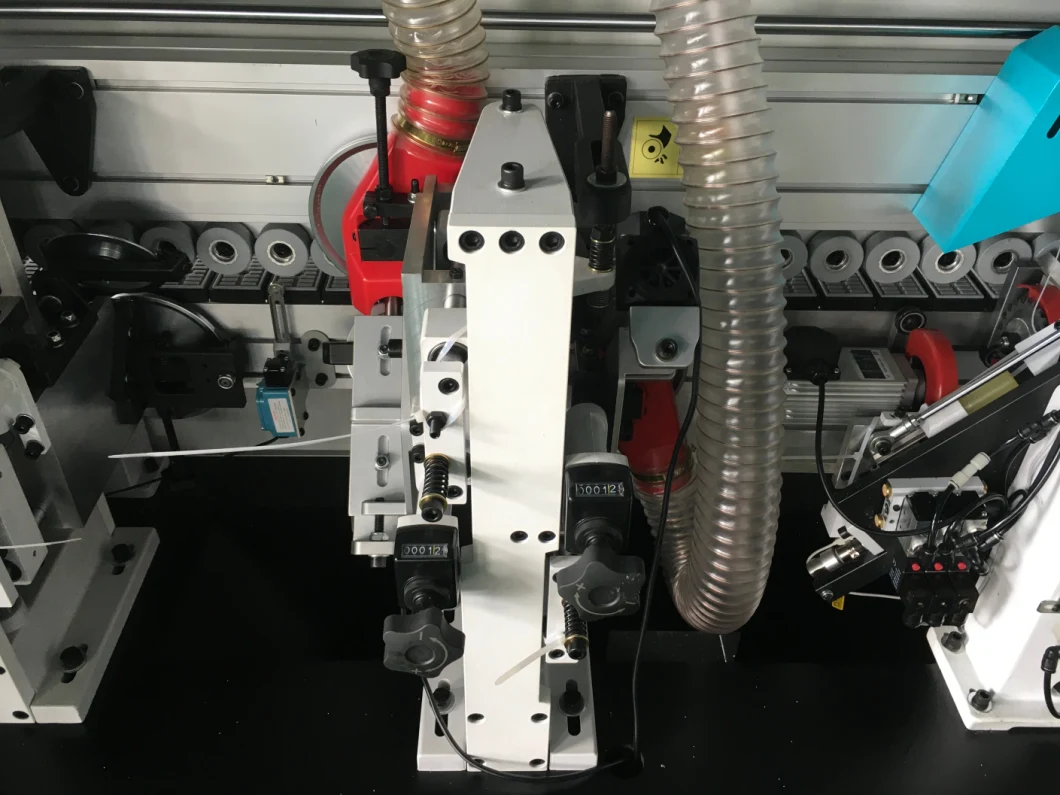

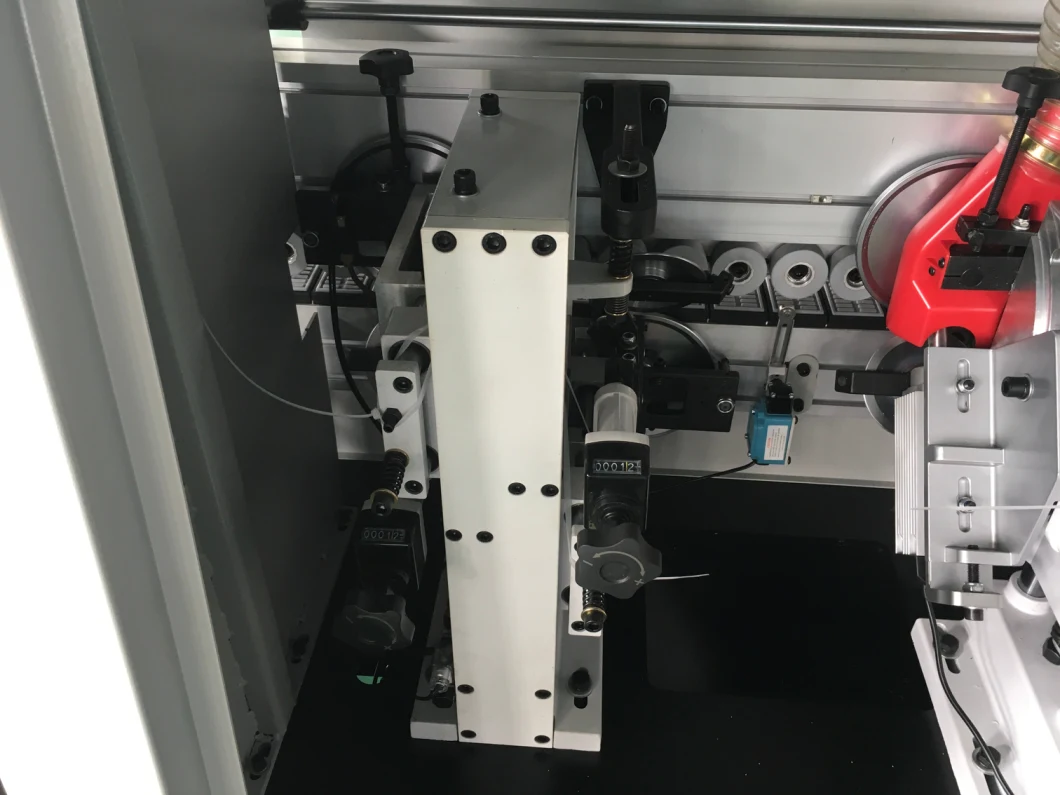

Mahcine pictures:

Machine parts :

1.Delta touch screen with PLC controller for machine control system

Workshop show

Edge Banding Machine Specifications

Fully automatic edge banding machine: Taiwan Delta LCD touch screen, Delta PLC intelligent integrated circuit board, Dully automatic edge banding machine: Taiwan Delta LCD touch screen, Delta PLC intelligent integrated circuit board, Delta inverter, imported Siemens contactor, improve the stability of the machine during use to extend the service life! Continuous plate blocking plate cylinder: Fully automatic edge banding machine with the function of the head. If the spacing of the continuous plate is too small, the head will be damaged by impact (the machine is equipped with the head protection function), and the function of the head protection is less than The spacing of the plates will automatically protect the conveyor from stopping, and the cylinders will work according to the reasonable distance of the plate to ensure the normal operation of the machine. Super-adhesive rubber, four-wheeled tape, the main sticker wheel is the driving wheel, which avoids the problem of shortage of adhesive tape and edge banding in the tape-attaching process, ensuring the flat fit of the edge banding and the board, and sticking It is firm and not easy to fall off. Head function: 45-degree single-rail front and rear head unit, equipped with Yadeke cylinder, Taiwan silver guide rail, Taiwan silver slider, alloy head saw blade, domestic famous brand factory motor, high precision and stable operation The front and back of the shortest sheet of 7 cm are precisely matched, with an electronic automatic oiler, which can set the automatic oil filling time according to the workload, ensuring smooth lubrication. Trimming function: 1. Rough repair with a flat knife with a suitable range of 0.4 veneer or edge banding thickness of 1.2 mm or more. The veneer is thin and brittle. The direct use of the finishing is easy to cause the veneer to rupture, 1.2 mm or more. The thickening of the edge banding is not as good as the individual finishing, and the assembly process adopts a 15 degree tilt to avoid scratching the plate during use. 2. Intensive use of 45 degree diagonal repairing knife in the process of trimming, the edge of the edge banding is in contact with the edge trimming knife to bring a certain degree of arc and it is not easy to damage the board. 3. The scraping edge adopts a 45-degree inclined R2 knife, and the trimmed sheet enters the scraping edge to make the upper and lower edges of the product smooth and round, which improves the product quality, and assembles the scraping waste scraping function to make the edge-sealing There is no waste residue on the surface of the product. The transmission motor is stable under the 2.2 kW Taiwan brand and has good durability. The upper and lower polishing is the process after the sealing is completed, and the remaining edema in the early stage is polished to achieve smooth and high quality requirements.elta inverter, imported Siemens contactor, improve the stability of the machine during use to extend the service life! Continuous plate blocking plate cylinder: Fully automatic edge banding machine with the function of the head. If the spacing of the continuous plate is too small, the head will be damaged by impact (the machine is equipped with the head protection function), and the function of the head protection is less than The spacing of the plates will automatically protect the conveyor from stopping, and the cylinders will work according to the reasonable distance of the plate to ensure the normal operation of the machine. Super-adhesive rubber, four-wheeled tape, the main sticker wheel is the driving wheel, which avoids the problem of shortage of adhesive tape and edge banding in the tape-attaching process, ensuring the flat fit of the edge banding and the board, and sticking It is firm and not easy to fall off. Head function: 45-degree single-rail front and rear head unit, equipped with Yadeke cylinder, Taiwan silver guide rail, Taiwan silver slider, alloy head saw blade, domestic famous brand factory motor, high precision and stable operation The front and back of the shortest sheet of 7 cm are precisely matched, with an electronic automatic oiler, which can set the automatic oil filling time according to the workload, ensuring smooth lubrication. Trimming function: 1. Rough repair with a flat knife with a suitable range of 0.4 veneer or edge banding thickness of 1.2 mm or more. The veneer is thin and brittle. The direct use of the finishing is easy to cause the veneer to rupture, 1.2 mm or more. The thickening of the edge banding is not as good as the individual finishing, and the assembly process adopts a 15 degree tilt to avoid scratching the plate during use. 2. Intensive use of 45 degree diagonal repairing knife in the process of trimming, the edge of the edge banding is in contact with the edge trimming knife to bring a certain degree of arc and it is not easy to damage the board. 3. The scraping edge adopts a 45-degree inclined R2 knife, and the trimmed sheet enters the scraping edge to make the upper and lower edges of the product smooth and round, which improves the product quality, and assembles the scraping waste scraping function to make the edge-sealing There is no waste residue on the surface of the product. The transmission motor is stable under the 2.2 kW Taiwan brand and has good durability. The upper and lower polishing is the process after the sealing is completed, and the remaining edema in the early stage is polished to achieve smooth and high quality requirements.

Pre-heatinggluing,end cutting rough trimming ,fine trimming ,scraping ,buffing

Mahcine pictures:

Machine parts :

1.Delta touch screen with PLC controller for machine control system

Workshop show

Edge Banding Machine Specifications

| Model | WJS-368 | |

| Panel Thickness | 10-60mm | |

| Edge Band Thickness | 0.4-3mm | |

| Panel Width | ≥60mm | |

| Panel Length | ≥150mm | |

| Feeding Speed | 15-23m/min | |

| Working Pressure | 0.6Mpa | |

| Voltage | 380V/50HZ/3PH | |

| Gluing Motor | 0.75KW 50HZ 1400RPM | |

| End Cutting Motor | 0.37KW * 2 200HZ 12000RPM | |

| Trimming Motor | 0.75KW * 4 200HZ 12000RPM | |

| Corner Trimming Motor | 0.37KW * 2 200HZ 12000RPM 0.75KW * 2 200HZ 12000RPM | |

| Buffing Motor | 0.37KW * 2 50HZ 1400RPM | |

| Conveyor Motor | 2.2KW | |

| Glue Pot Heating Power | 2.4KW | |

| Lighting Power | 0.05KW | |

| Lifting Motor | 0.25KW | |

| Total Power | 12.4KW | |

| Dimension | 4800*1000*1650mm | |

| Wooden Crate Package | 4860*1050*1760mm | |

Fully automatic edge banding machine: Taiwan Delta LCD touch screen, Delta PLC intelligent integrated circuit board, Dully automatic edge banding machine: Taiwan Delta LCD touch screen, Delta PLC intelligent integrated circuit board, Delta inverter, imported Siemens contactor, improve the stability of the machine during use to extend the service life! Continuous plate blocking plate cylinder: Fully automatic edge banding machine with the function of the head. If the spacing of the continuous plate is too small, the head will be damaged by impact (the machine is equipped with the head protection function), and the function of the head protection is less than The spacing of the plates will automatically protect the conveyor from stopping, and the cylinders will work according to the reasonable distance of the plate to ensure the normal operation of the machine. Super-adhesive rubber, four-wheeled tape, the main sticker wheel is the driving wheel, which avoids the problem of shortage of adhesive tape and edge banding in the tape-attaching process, ensuring the flat fit of the edge banding and the board, and sticking It is firm and not easy to fall off. Head function: 45-degree single-rail front and rear head unit, equipped with Yadeke cylinder, Taiwan silver guide rail, Taiwan silver slider, alloy head saw blade, domestic famous brand factory motor, high precision and stable operation The front and back of the shortest sheet of 7 cm are precisely matched, with an electronic automatic oiler, which can set the automatic oil filling time according to the workload, ensuring smooth lubrication. Trimming function: 1. Rough repair with a flat knife with a suitable range of 0.4 veneer or edge banding thickness of 1.2 mm or more. The veneer is thin and brittle. The direct use of the finishing is easy to cause the veneer to rupture, 1.2 mm or more. The thickening of the edge banding is not as good as the individual finishing, and the assembly process adopts a 15 degree tilt to avoid scratching the plate during use. 2. Intensive use of 45 degree diagonal repairing knife in the process of trimming, the edge of the edge banding is in contact with the edge trimming knife to bring a certain degree of arc and it is not easy to damage the board. 3. The scraping edge adopts a 45-degree inclined R2 knife, and the trimmed sheet enters the scraping edge to make the upper and lower edges of the product smooth and round, which improves the product quality, and assembles the scraping waste scraping function to make the edge-sealing There is no waste residue on the surface of the product. The transmission motor is stable under the 2.2 kW Taiwan brand and has good durability. The upper and lower polishing is the process after the sealing is completed, and the remaining edema in the early stage is polished to achieve smooth and high quality requirements.elta inverter, imported Siemens contactor, improve the stability of the machine during use to extend the service life! Continuous plate blocking plate cylinder: Fully automatic edge banding machine with the function of the head. If the spacing of the continuous plate is too small, the head will be damaged by impact (the machine is equipped with the head protection function), and the function of the head protection is less than The spacing of the plates will automatically protect the conveyor from stopping, and the cylinders will work according to the reasonable distance of the plate to ensure the normal operation of the machine. Super-adhesive rubber, four-wheeled tape, the main sticker wheel is the driving wheel, which avoids the problem of shortage of adhesive tape and edge banding in the tape-attaching process, ensuring the flat fit of the edge banding and the board, and sticking It is firm and not easy to fall off. Head function: 45-degree single-rail front and rear head unit, equipped with Yadeke cylinder, Taiwan silver guide rail, Taiwan silver slider, alloy head saw blade, domestic famous brand factory motor, high precision and stable operation The front and back of the shortest sheet of 7 cm are precisely matched, with an electronic automatic oiler, which can set the automatic oil filling time according to the workload, ensuring smooth lubrication. Trimming function: 1. Rough repair with a flat knife with a suitable range of 0.4 veneer or edge banding thickness of 1.2 mm or more. The veneer is thin and brittle. The direct use of the finishing is easy to cause the veneer to rupture, 1.2 mm or more. The thickening of the edge banding is not as good as the individual finishing, and the assembly process adopts a 15 degree tilt to avoid scratching the plate during use. 2. Intensive use of 45 degree diagonal repairing knife in the process of trimming, the edge of the edge banding is in contact with the edge trimming knife to bring a certain degree of arc and it is not easy to damage the board. 3. The scraping edge adopts a 45-degree inclined R2 knife, and the trimmed sheet enters the scraping edge to make the upper and lower edges of the product smooth and round, which improves the product quality, and assembles the scraping waste scraping function to make the edge-sealing There is no waste residue on the surface of the product. The transmission motor is stable under the 2.2 kW Taiwan brand and has good durability. The upper and lower polishing is the process after the sealing is completed, and the remaining edema in the early stage is polished to achieve smooth and high quality requirements.