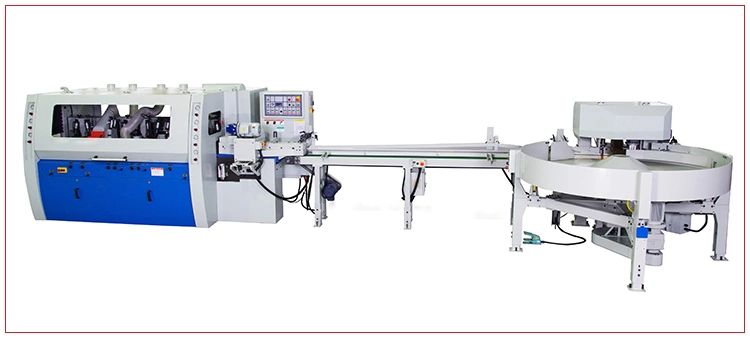

5 Spindle Woodworking Automatic Four Side Planer Moulder For Sale

Description

| Model | HC520GH |

| Working width | 20-200mm |

| Working thickness | 8-125mm |

| Min processing length(continuously / non-continuously) | 150/159mm |

| Active working table lifting stroke | 7mm |

| Active limit bar lifting stroke | 8mm |

| Spindle speed | 8000r/min |

| Feeding speed | 10-60m/min |

| spindle | 5 |

| Spindle diameter | 40mm |

| Cutter diameter | 125*40*18mm |

| Feeding wheel diameter | 140*35*50mm |

| Machine power | 38.85kw |

| 1st bottom spindle | 5.5kw |

| Right spindle | 5.5kw |

| Left spindle | 5.5kw |

| 1st upper spindle | 7.5kw |

| 2nd upper spindle | / |

| 2nd bottom spindle | 5.5kw |

| Feeding power | 7.5kw |

| Beam Lifting power | 0.75kw |

| belt conveyor power | 1.1kw |

| Left axle feeding motor | 0.75kw |

| Centrifugal disc conveyor power | 3kw |

| Dust collection port diameter | 120mm*5pc |

| Gas floating pressure | 0.3-0.6mpa |

| Machine size | 3630*1790*1750mm |

| Machine weight | 4300KG |

Product Usage:

This product is mainly based on the requirement of efficient and automatic production in the large number of solid wood processing industry. The centrifugal disc conveyor is equipped for automatic feeding, which goes into the longitudinal conveyor and then into the high-speed four-sided plane. The automatic four-way reimbursement processing of feeding materials, especially the high-speed four-way planing with groove positioning structure, can overcome the phenomenon of running materials and sticking materials in the normal four side planer short materials processing. Its maximum processing width is 200mm, its maximum processing thickness is 125mm, its minimum processing length is 150mm (continuous), and its feeding speed is 10-60m/min. It is an ideal equipment to realize the upgrading and upgrading of solid wood processing industry.

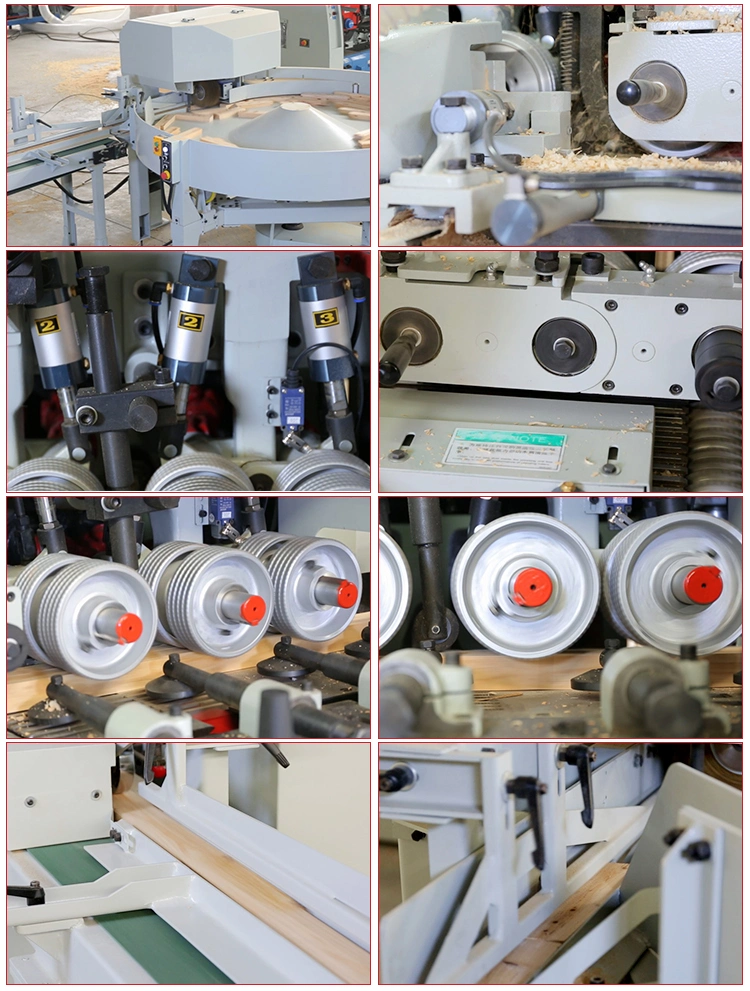

Sample

About Us

1.15 years experience in chinese woodworking machinery market.

2. 8 years exportation experience, have customers in more than 40 countries.

3.Engineer team with +20 years experience.

4.Diamond supplier in made-in-china.

5.Our products are widely sold in made-in-china.

6.Guarantee and After-sale service:

a. 12 months warranty for the whole machine

b. Technical support by phone, email or WhatsApp/Skype around the clock.

c. Friendly English version manual and operation video CD disk

d. Engineer available to service machinery overseas.

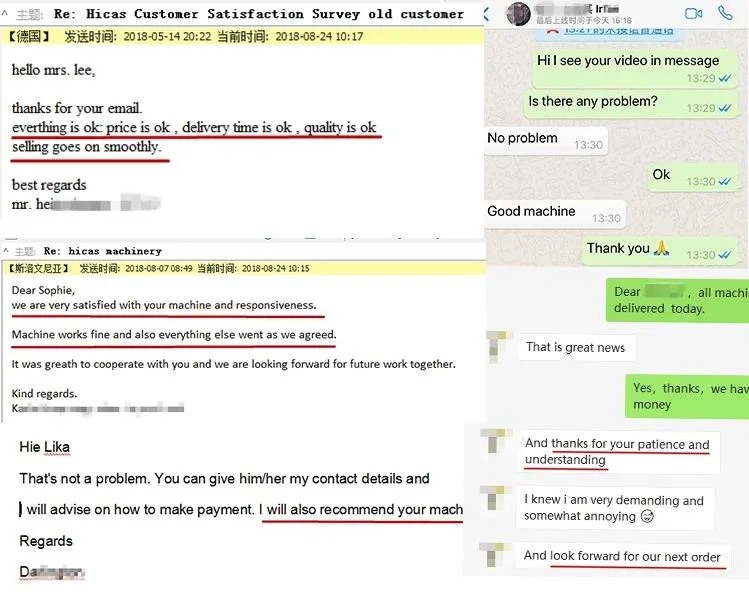

7. Customer feedbacks

8.Our company and products have been verified onsite by SGS Group

We are looking for Good customers like you! and Distributor or Agents Wanted!!!